Pizza Capers, The Entrance

Prior to the project commencing, an issue was reported with the ground floor tenancies which occupied a ten-story apartment high rise block. The issue was

Prior to the project commencing, an issue was reported with the ground floor tenancies which occupied a ten-story apartment high rise block. The issue was

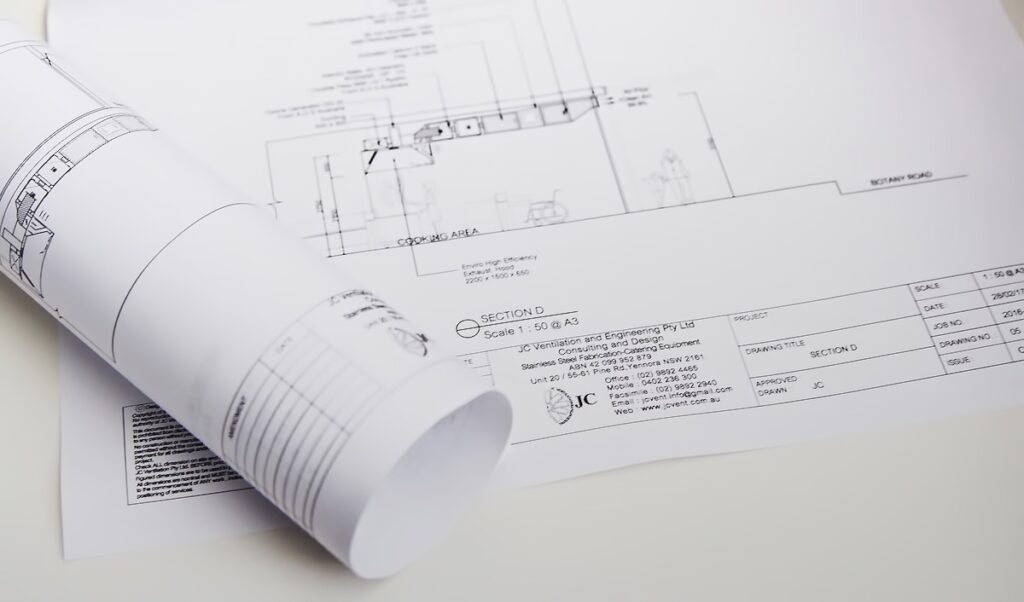

A Tavola is one of Sydney’s most loved Italian restaurants. JC Ventilation was to work on a new store which was opening in Bondi. The

The Civic Cafe was a new cafe at a location that was formally a Civic Video store. The Civic Cafe project consisted of: – 1

Whether you have a small or large project, we have the expertise in helping with your next project. We would love to hear from you.